In industrial and commercial electrical systems, modularity is no longer a “nice to have,” but a fundamental requirement to meet the growing demands for flexibility, rapid installation, simplified maintenance, and scalability. For those who design, install, or manage electrical systems, and even for those approaching the field for the first time, it becomes crucial to rely on solutions that are pre-engineered , efficient , and intelligent during the design phase.

The range of busbar trunking systems produced by Graziadio & C. , from 25 to 6,300 A, represents a consolidated “Made in Italy” reality for the transmission and distribution of electrical energy.

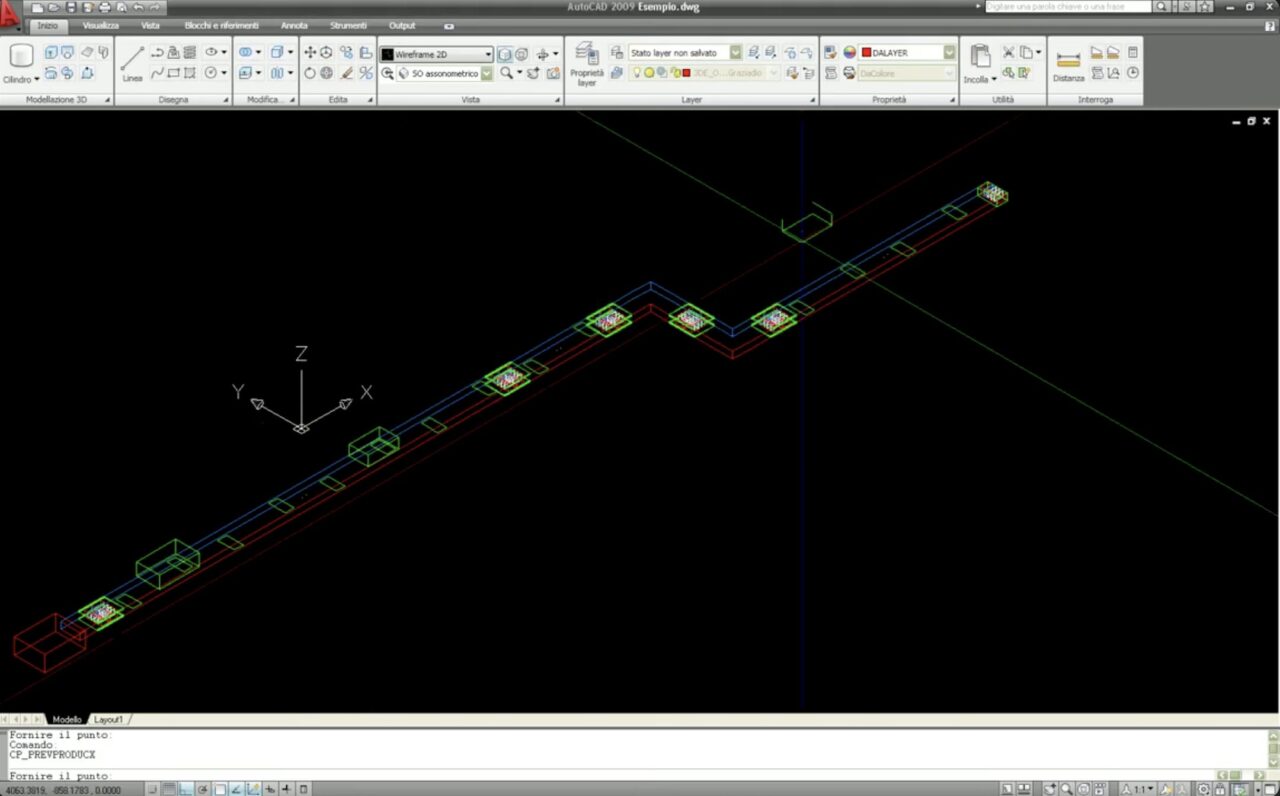

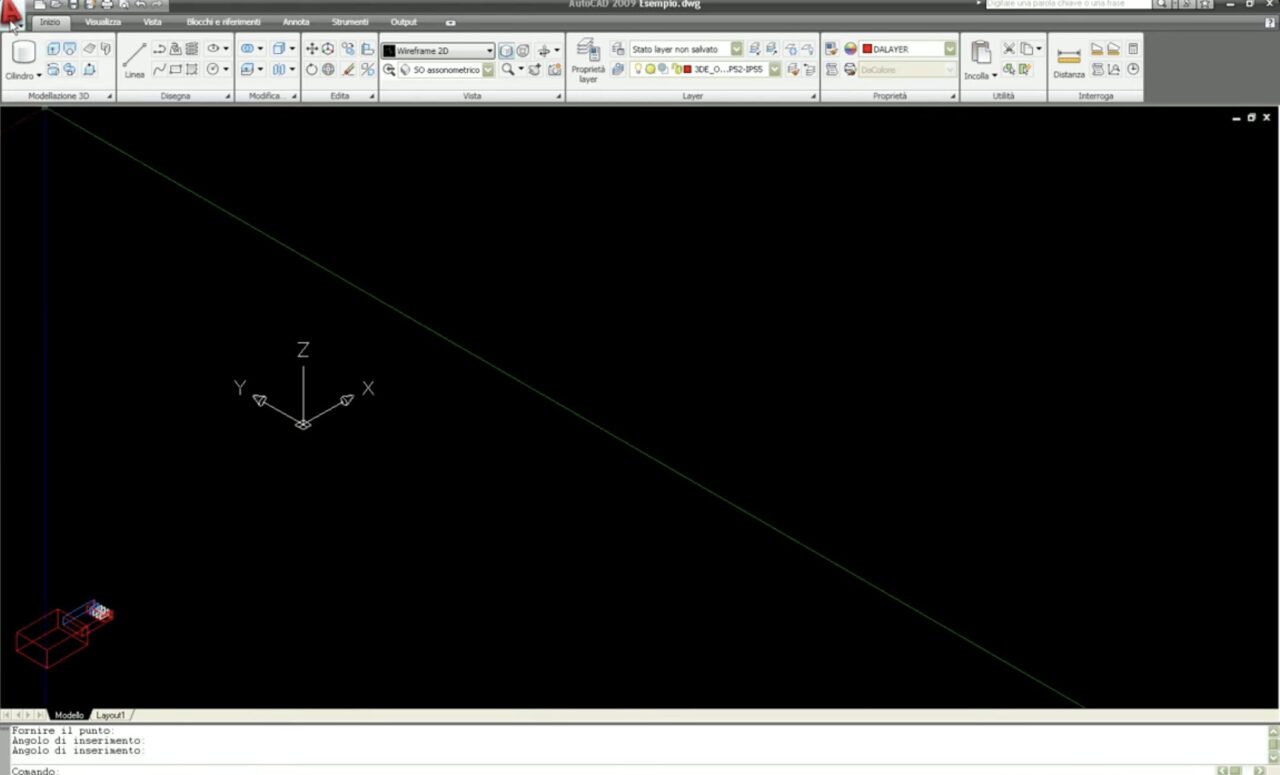

To support designers and technicians in their layout and design activities, Graziadio has developed BlindoCad , a modern software integrated into AutoCAD (and compatible with other CAD programs) that allows for 2D and 3D modelling of busbar trunking systems, composing straights, bends, end caps, junction boxes, and accessories, and automatically generating the bill of materials (BoM).

This article aims to guide even those who are not very familiar with busbar systems or specialized CAD software: you will discover why designing modular systems is advantageous, how to approach the design with BlindoCad , and what are the concrete benefits that derive from it for designers, installers and end customers.

Why modularity in electrical systems?

A modular electrical system is based on the logic of standardized, prefabricated, or semi-prefabricated components, which allow for rapid assembly, easy future modifications, and efficient maintenance. Why does all this matter?

Main benefits

- Reduced design and installation time and costs: the use of blocks, libraries, and modules allows you to bypass most “from scratch” customizations.

- Increased system flexibility: the ability to adapt to changes or expansions without redoing the entire route.

- Easier maintenance: easier access, foreseen branches, possibility of modifications without invasive interventions.

- Greater reliability and quality: a designed and prefabricated system reduces errors on site, downtime and compatibility risks.

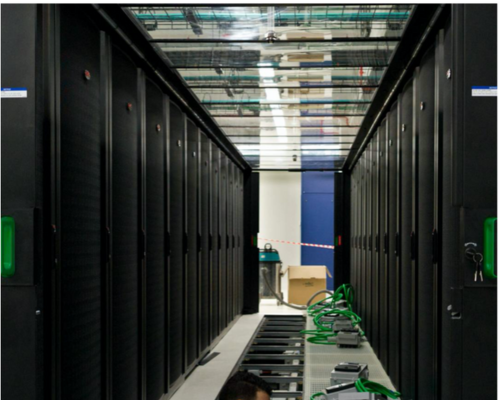

In the case of Graziadio busbar trunking, these features are emphasized: in fact, the documentation highlights how the systems are designed for quick assembly, “plug & play” installation, high degree of protection up to IP 68 (for some ranges) and the possibility of revision and reuse even after decades.

Typical design challenges (complex spaces, high power management, coordination between power supply/distribution, safety regulations) find a concrete answer in modular solutions.

The role of BlindoCad in modular design

BlindoCad is a strategic tool in the design workflow: it allows you to transform ideas and diagrams into executive technical layouts, connecting directly to the Graziadio busbar trunking system.

Software Overview

- It is fully integrated into AutoCAD and compatible with many versions of AutoCAD and other CAD/cloud partners.

- It allows 2D and 3D design of the entire system: duct layout, module definition, insertion of curves, connections, and headers.

- Includes updated libraries of Graziadio products: from the GLS series, J Series, GDA/GDR, K Series, ISOLSBARRA, etc.

- Automatic generation of the Bill of Materials (BoM): each element is recognized, the lengths are calculated, the accessories are matched.

- Continuous updates and adaptation to new design needs.

These elements make BlindoCad not just a drawing software, but an integrated design engine that enhances modularity, reduces errors and simplifies the transition from design to installation.

Step-by-step: designing a modular system with BlindoCad

Below is a general flow (customizable for each project) that guides from definition to execution, using BlindoCad and integrating the modularity of the busbar trunking.

Phase 1 BlindoCad: Definition of specifications

Phase 1 BlindoCad: Definition of specifications

- Identify the required current rating (e.g. 630 A, 2000 A, 5000 A) and select the correct range (e.g. GDA for 63-2500 A) from Graziadio solutions.

- Check the installation environment and conditions: internal/external, required degree of protection (e.g. IP66, IP68).

- Define general layout: route, power points, branches, space maintenance, support brackets.

Phase 2: Creating the basic 2D layout

- Open BlindoCad within CAD, select the busbar trunking range from the library menu.

- Drawing straight elements: defining standard lengths and connection points.

- Insert fittings and corners: BlindoCad libraries allow you to choose curves, corners < 90°, T-junctions, double horizontal/vertical heads.

- Define junction boxes, brackets, expansion elements, end caps: all available in the library.

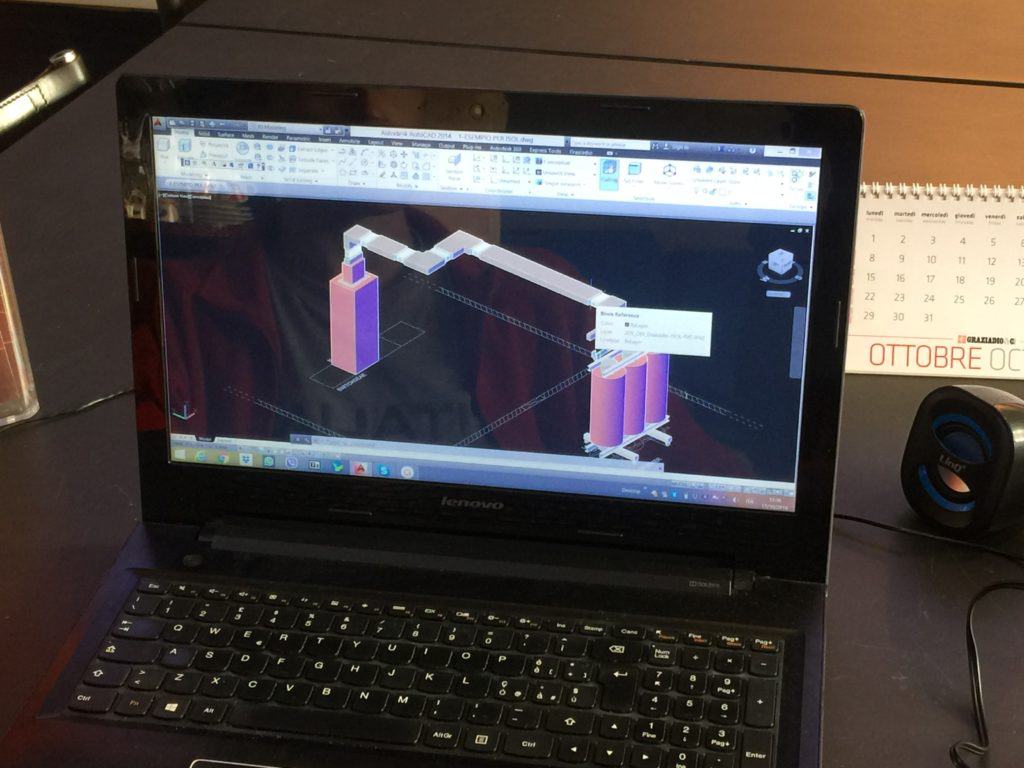

Step 3: Transpose to 3D and verify

- Switch to the 3D model to check for interference, vertical or horizontal paths, brackets, and any space restrictions.

- Using 3D allows you to anticipate assembly errors, reduce rework in the field and ensure that modules are compatible.

- Check any details such as brackets for vertical lines, renewed spans.

Phase 4: Using the Product Library and Selecting the System

- Select the appropriate busbar trunking system (e.g. ISOLSBARRA for 630-6300 A transport).

- Customize editable parameters: length, materials (copper or aluminium), head type (“P”, “TT”), brackets, connections.

- Check the electrical, mechanical and spatial compatibility of the chosen system.

Step 5: Generate the BoM and executive documentation

- With one click, BlindoCad generates the bill of materials: each module, accessory, and length is reported.

- Prepare working drawings, 3D exploded views, sections and assembly details to be delivered to the installer.

- Provide a modular assembly plan: prefabricated elements ready for installation, brackets and fixings already defined.

- See the BlindoCad Installation and Uninstallation Guide (PDF) for technical details on installing the software.

Final phase: Field integration and implementation

- The use of a modular design (prefabricated busbar trunking) significantly reduces construction times, errors and delays.

- Assembly is more straightforward: pre-defined modules, compatible elements, brackets and fittings included in the project.

- Anticipate future modifications/expansion: thanks to its modularity, the system is scalable and reconfigurable.

Benefits and practical use cases

For designers, installers and end customers, adopting a modular approach supported by BlindoCad and Graziadio busbar systems brings concrete advantages:

- Reduced design and installation times : less time spent defining every single detail thanks to pre-engineered libraries and a simplified design flow.

- Reduce errors and rework on the jobsite : The 3D model and automated bill of materials help predict problems before installation.

- Greater scalability and flexibility : the system can be expanded or modified in the future with lower costs and time.

- High quality and “Made in Italy” certification : Graziadio systems have been produced for decades, with high reliability.

- Operational and maintenance efficiency : the modular structure facilitates interventions and reduces plant downtime.

Best practices and technical tips

To make the most of BlindoCad and the modularity of the busbar trunking, here are some useful tips:

- Always keep the product library in the software up to date: new parameters and new ranges are continuously implemented.

- Always check CAD compatibility: BlindoCad supports AutoCAD (from 2004 to 2024) and many other CADs.

- Plan for branching points from the start: Modularity is maximized when modules enable future applications.

- Take care of the executive documentation : 3D drawings, sections, bill of materials, exploded views are essential for error-free installation.

- Consider regulatory and safety requirements: for example, protection rating (IP66, IP68), materials, brackets, vertical/horizontal positioning.

- Don’t neglect the assistance and assembly phase: thanks to the modular design, you get faster on-site and easier future interventions.

Conclusion

Designing a modular electrical system using dedicated software like BlindoCad and integrating Graziadio busbar trunking systems offers a significant competitive advantage today. For those new to the subject, it represents a guided entry into the world of modularity; for the experienced designer, it is a tool that simplifies and speeds up the work.

We invite you to book a call with Graziadio’s technical team today for direct support. Take advantage of the combination of intelligent design and prefabricated Made in Italy products to build modular, efficient, scalable electrical systems that are ready for future needs.