In a constantly evolving sector such as the industrial one, energy efficiency and plant safety are absolute priorities. Electricity distribution plays a crucial role in ensuring operability and reliability, especially in high-intensity contexts such as production plants, data centres and large infrastructures. In this scenario, busbar trunking emerges as the most advanced technological solution to optimize energy transport, reducing waste, simplifying installation and ensuring exceptional durability over time.

But what makes busbar trunking so high-performing compared to traditional systems? In this article we will explore every detail, highlighting the advantages, structure and main fields of application.

What is busbar trunking?

Busbar trunking is a modular system designed to distribute electrical energy safely and efficiently.

Unlike traditional electrical wiring, it uses conductive bars enclosed in an insulating and protective casing.

This system allows for the transport of large amounts of current with reduced dimensions and maximum safety, making it ideal for industrial applications, strategic infrastructures, large commercial and civil buildings.

What does busbar trunking look like?

Busbar trunking consists of:

- Conductive bars made of copper or aluminium, which transport energy.

- Insulating sheath (in PVC or advanced thermoplastic materials) that guarantees electrical and mechanical protection.

- External metal or plasticized structure for protection from impacts, atmospheric agents, water and dust.

- Quick couplings and modular systems for simple and safe connections.

Depending on the needs, busbar trunking can have different characteristics:

- Resistance to extreme conditions (high temperatures, humid environments)

- High protection levels ( IP66, IP68 )

- Easy expansion and modification without invasive intervention

Why choose busbar trunking instead of traditional cables?

In recent years, busbar trunking has become the preferred choice for industrial plants due to its numerous advantages:

- Superior safety: thanks to insulation, protection from dust and water (with protection levels up to IP68 ).

- Quick installation : pre-assembled modules allow for shorter installation times compared to traditional cables.

- Simplified maintenance : the components are easily inspected and replaced.

- Modularity : the system can be expanded, modified or adapted without invasive demolition.

- Energy efficiency: energy loss is reduced, increasing overall efficiency.

Although cables are still used in many plants, in advanced industrial contexts the busbar trunking is establishing itself as the standard for a series of concrete reasons:

Comparison table

| Characteristic | Bus duct | Traditional cables |

| Safety | Very high (IP66–IP68) | Media (requires channelling) |

| Installation time | Fast, modular | Slower and more complex |

| Future expandability | Very easy (adding modules) | Complex (new wiring) |

| Energy efficiency | High (less dispersion) | Lower (cable losses) |

| Inspection and maintenance | Simple and fast | Difficult |

| Average implant lifespan | >30 years | 10–15 years |

Conclusion : Busbar trunking is safer, quicker to install, longer-lasting and more flexible than traditional wiring.

Where is busbar trunking used?

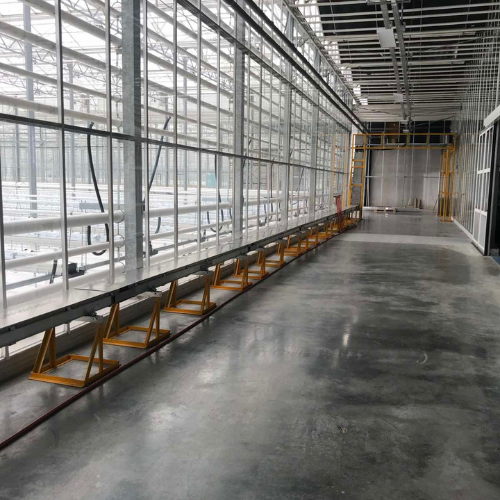

Thanks to their versatility and reliability, busbar trunking is used in:

- Industrial plants ➔ where continuous power without interruptions is required.

- Airports ➔ to support critical infrastructure such as lighting and security systems.

- Tunnels and subways ➔ harsh environments where protection against humidity is essential.

- Hospitals and large healthcare facilities ➔ safe power supply for life-saving equipment.

- Data centre ➔ continuous and easily changeable power supply.

- Strategic infrastructures ➔ such as the Pedemontana Veneta highway , where Graziadio has made an important supply.

Graziadio’s added value: ISOLSBARRA

Among the most popular solutions, ISOLSBARRA stands out , the flagship busbar duct designed by Graziadio.

Main features of ISOLSBARRA:

- Range from 630A up to 6300A.

- IP66 and IP68 certification , for complete protection against dust and water.

- Modular, flexible and easily inspectable structure.

- Made entirely in Italy, with high quality materials.

- Dedicated technical support from design to installation.

Discover ISOLSBARRA here.

Quick answers on busbars

When is it best to use busbar trunking?

When the system requires high transport currents, continuous reliability, ease of maintenance or future modular expansion possibilities.

Are busbars more expensive than cables?

At the purchasing stage, ducts may seem more expensive, but considering reduced installation times, longer life and minimal maintenance, the overall cost is often lower.

How long does busbar trunking last?

A properly installed system can last more than 30 years of operation without the need for major replacements.

Discover the future of electrical distribution

Choosing a busbar trunking means adopting a safe, efficient and long-lasting technology.

Graziadio offers tailor-made solutions, supported by 65 years of experience and innovation Made in Italy.

Contact us to find out how we can support your project.

Find out more at www.graziadio.co.uk