Power Busbar Installed In Coventry

When a precision engineering company relocated to a brand new purpose built unit, a requirement was quickly identified for an easier, quicker and more cost effective way of supplying the power to the lighting and machinery. After various design discussions with the appointed Electrical Contractor, AJA Contracts, Graziadio UK were able to assist by supplying both GLS Lighting Busbar and GDA Power Busbar.

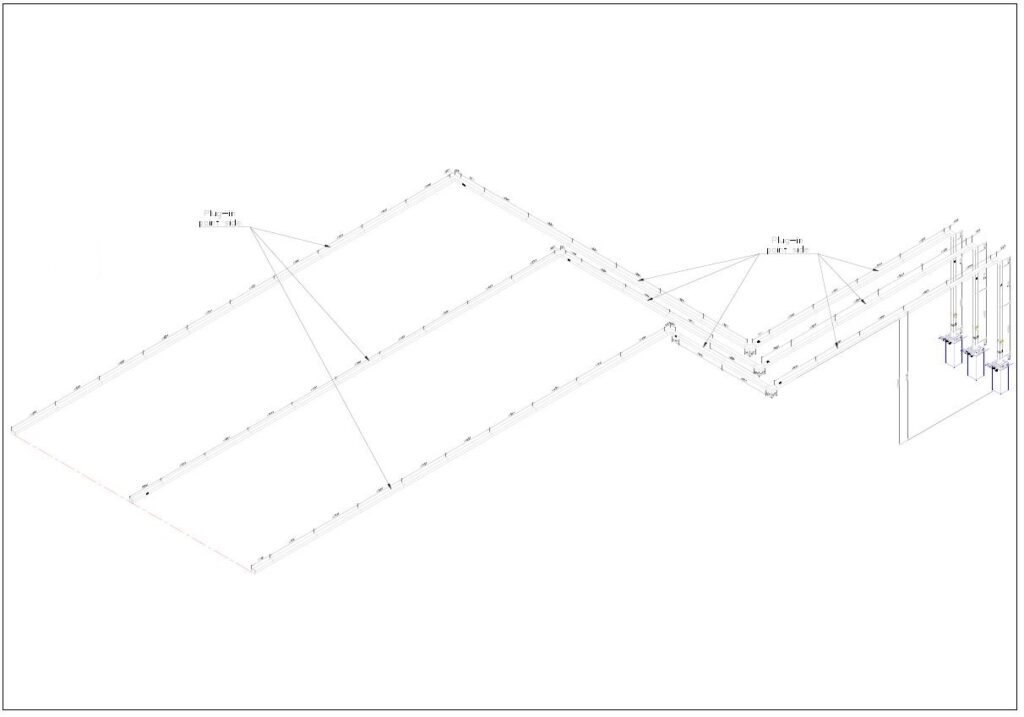

Firstly, Graziadio 40A 6 pole GLS Lighting Busbar was supplied to allow the fast and economical installation of LED lighting and a flexible system for any future alterations. The 6 pole solution gave the option to incorporate the main lighting, emergency lighting, and Dali controls within a single busbar system and was therefore a very cost effective solution overall.

This part of the project was supplied in it’s entirety from UK stock and arrived on site the day after the initial order was placed.

A final layout using Graziadio 400A GDA power busbar was approved. Due to the layout a number of bespoke lengths were required together with tee units and bends. Once the design was agreed and the order placed, Graziadio were able to manufacture the goods and have them ready for shipping just 14 working days from the date of order.

Not only that, enforced changes on site meant some last minute amendments needed to be made to the power busbar order. The day before it was due to leave our factory in Italy we were advised that an additional custom made length and flat bend would be required, and the end feed unit also needed to be changed for a different type.

The flexibility of the Graziadio factory in Italy was put to the test, and they were able to manufacture the custom length that afternoon, and add all the extra items to the original order which meant that it still left the factory on time the following day.

Once on site, each part of the project only took a few days to install, and the project was completed on schedule.