The choice of busbar trunking directly impacts the safety, continuity of service, and total cost of ownership (TCO) of a system. A properly sized and certified system reduces unplanned downtime, simplifies future expansions, and maintains stable power distribution under all operating conditions.

In this article, we analyze the 5 most common mistakes made when selecting and designing a busbar trunking system , with practical suggestions for avoiding them and concrete examples of Graziadio lines that help prevent any critical issues.

Why the busbar trunking is the main element of the distribution

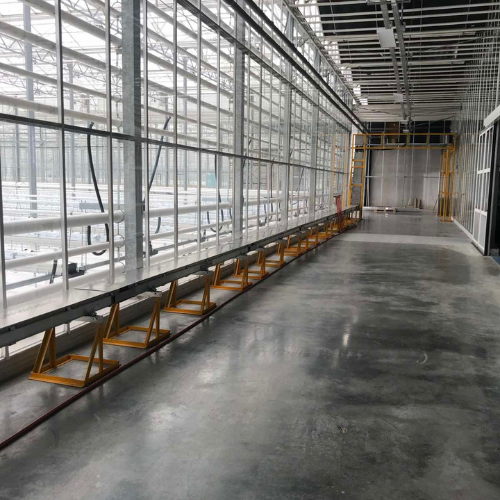

In many industrial plants, manufacturing plants, logistics facilities, data centers, hospitals, and airports, busbar trunking is the backbone of distribution: it connects electrical panels, powers backbones and process lines, and delivers energy safely and orderly to where it’s needed.

Compared to traditional cables it offers significant advantages:

- Higher current density

- Orderly paths and less clutter

- Faster installation

- Modularity and possibility of specific derivations

Precisely because it is the heart of the system, errors in the selection or sizing phase can cause overheating, voltage drops, maintenance difficulties and non-compliance with regulations.

Mistake 1 – Undersizing the flow rate

Problem

Often the busbar trunking is chosen “flush” with the current absorption, neglecting:

- Load peaks due to start-ups or production cycles

- Environmental conditions that influence the permissible flow rate

- Growth margin for future expansions

Risks

Overheating, insulation degradation, reduced service life, and abnormal voltage drops.

How to avoid it

- Collect realistic load profiles

- Apply correct environmental coefficients

- Consider voltage drop and reserve margin

Graziadio Solutions

- GDA/GDR – 63-250 A

- K SERIES – 800-5000 A

- ISOLSBARRA – 630-6300 A and ISOLFLEX – 630-6300 A

- J SERIES – 63-160 A

- PRODUCTOR – 50-400 A

Error 2 – Ignoring the installation environment

Problem

Underestimating the IP rating or corrosion resistance can lead to failure and premature degradation.

How to avoid it

- Evaluate humidity, dust, chemical agents, washing and temperature

- Choose compatible casings and gaskets

- Design routes that avoid water stagnation

Graziadio Solutions

Mistake 3 – Neglecting short circuit resistance

Problem

A busbar trunking may be suitable for the rated current but not sufficiently certified to withstand the stresses of a short circuit.

How to avoid it

- Know the presumed short circuit current and the intervention time of the protections

- Choose ducts with type tests suitable for the required Icw/Ipk

- Check for correct tightening and grounding

Graziadio Solutions

Mistake 4 – Not designing flexibility

Problem

“Closed” systems without provision for branches or expansions require complex and costly interventions.

How to avoid it

- Provide strategic branch points

- Plan extra flow in critical sections

- Use modular systems

Graziadio Solutions

Mistake 5 – Saving on quality and certifications

Problem

A cheap product without adequate certifications can lead to hidden costs and operational risks.

How to avoid it

- Check type tests and documentation

- Check the availability of spare parts

- Rely on qualified technical support

Graziadio Solutions

Use cases and applications

- Manufacturing and Automation: GLS, MULTICONDUCTOR, GDA, J SERIES

- Logistics and Large-Scale Retail: K SERIES, GDA/GDR, J SERIES

- Data centers: K SERIES, ISOLSBARRA, GDA

- Food Industry: ISOLSBARRA, GDA

- Civil Infrastructure: GDA/GDR, K SERIES, GLS

Quick checklist

- Load profiles and peaks

- Voltage drop

- Installation environment

- Short circuit resistance

- Modularity and sockets

- Installation and accessories

- Documentation and certifications

- Spare parts and assistance availability

Avoid these 5 mistakes

It means having a safe, continuous, and sustainable electrical distribution over time. Graziadio offers a full range of solutions, from light distribution to high-current backbones and medium voltage, with technical support at every stage.

Discover the entire Graziadio range and request a consultation for your system.